Mechanical Cracking of Heavy crude oil

Azar Energy Tabriz Co. as a designer and producer of oil , gas and petrochemical equipment has designed and constructed the exclusive mechanical cracking machine with the help of experienced engineers and native experts and modern knowledge.

With applying this machine, the heavy components of heavy oil are cracked and changed to light components so the API degree increases and the viscosity of crude's decreases considerably.

The pilot plant of this machine has been constructed with the capacity of 1000 PBD for the oil cracking of Iran's Surush field. According to the test conducted and approved by Iranian Oil Industry Research Centre , result show that API degree has increased from 18 to 27 and the viscosity has decreased to 1/4 compared to the original one.

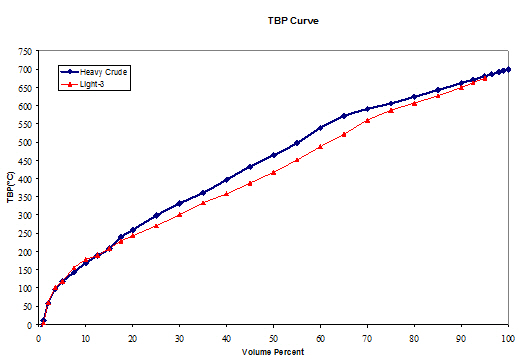

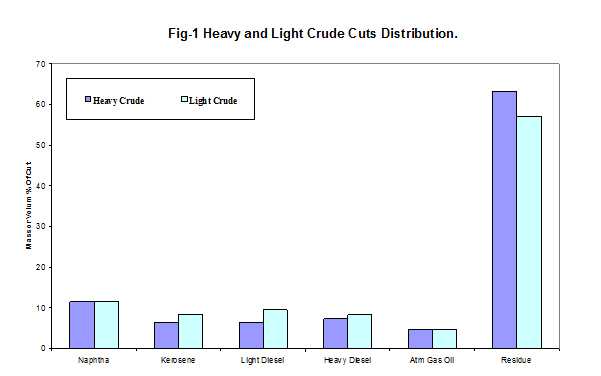

The exact verification (TBP curve) of the results show that asphaltenes components and heavy paraffin's converted to intermediate components such as Naphtha ,Gasoline and Kerosene in this method.

In Contrast with the conventional methods of oil cracking , in this method heavy oil is converted to light oil with the help of simple physical rules and energy conversion with minimum operating cost . Some of the advantages of mechanical cracking method are as follows :

1 . It dose not need heat supply systems which have high operating cost and require complex operations .

2 . No need to utility plants such as steam and water .

3 . The process is simple and has a minimum volume requirement .

4 . No need to complex piping and instrumentation .

5 . Increase in oil volume and surplus because of increase in oil API degree .

6 . The easy precommissioning and commissioning and low operating cost .

7 . Low maintenance cost .

8 . Decrease in Sulphur content of oil .

9 . No catalyst requirement .

A Brief Description of the Unit :

the feed enters the feed pump with 70 psig pressure and is pumped to the cracking unit with 650 psig pressure . Outlet light product together with light gases is sent to the flash separator . Separated gas by using ejector and a jet pump will be mixed with the liquid and will be sent to the existing plant with the 500 psig pressure . The simulation results of the plant can be observed in the diagrams.