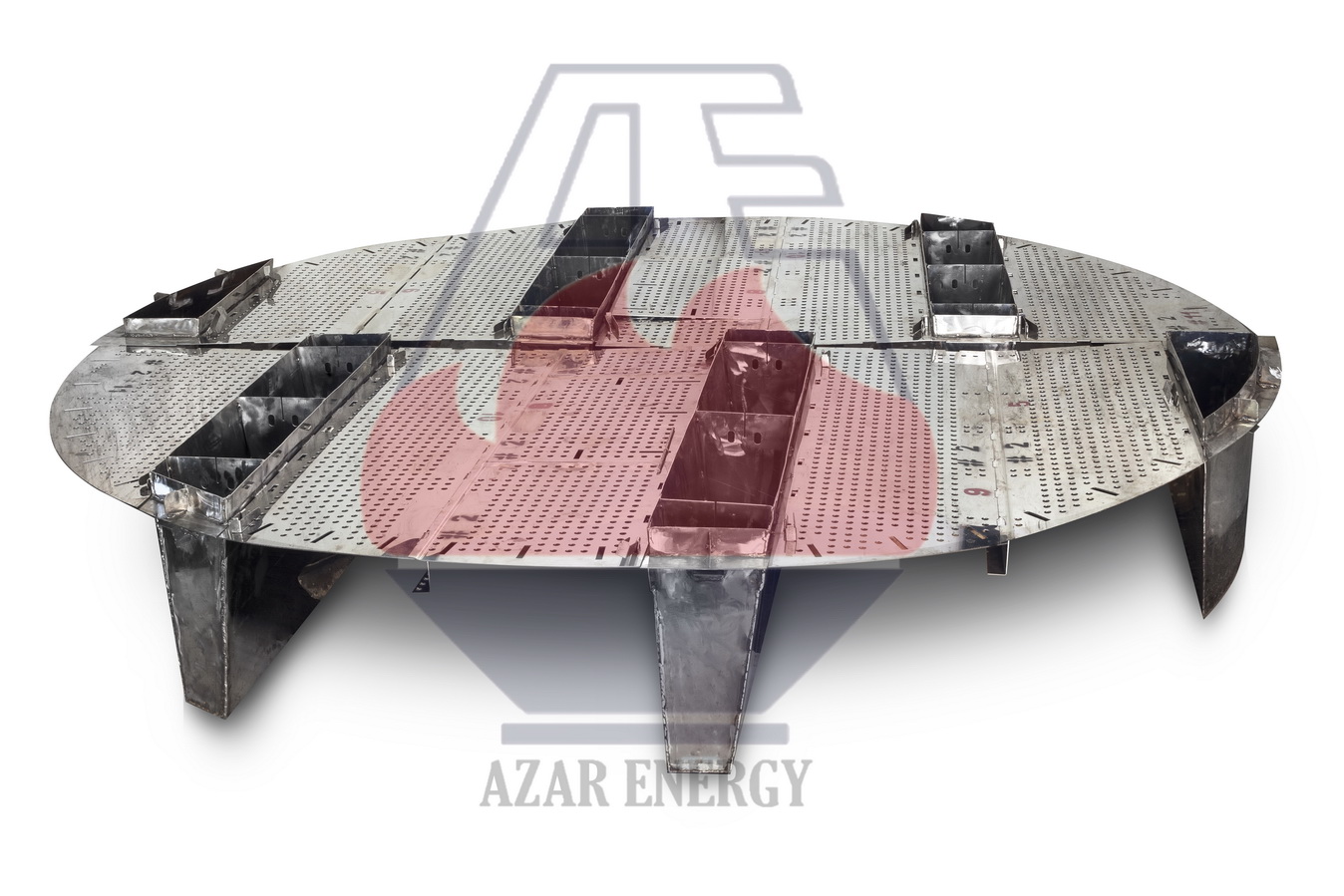

Sieve trays are the first and most common type of tray that has a lot of experiences in design and application. The Deck of these trays are perforated uniformly. Sieve trays are common with holes as small as 0.25 inches to 1 inch. Vapor flow rate through the trays, is controlled by the hole diameter design and the number of holes. Determination of vapor exit velocity through the holes is very important. The balance must be in place between the vapor discharge force and the liquid head on the tray, to prevent the fluid from dripping through the holes, and to prevent entrainment to upper tray.