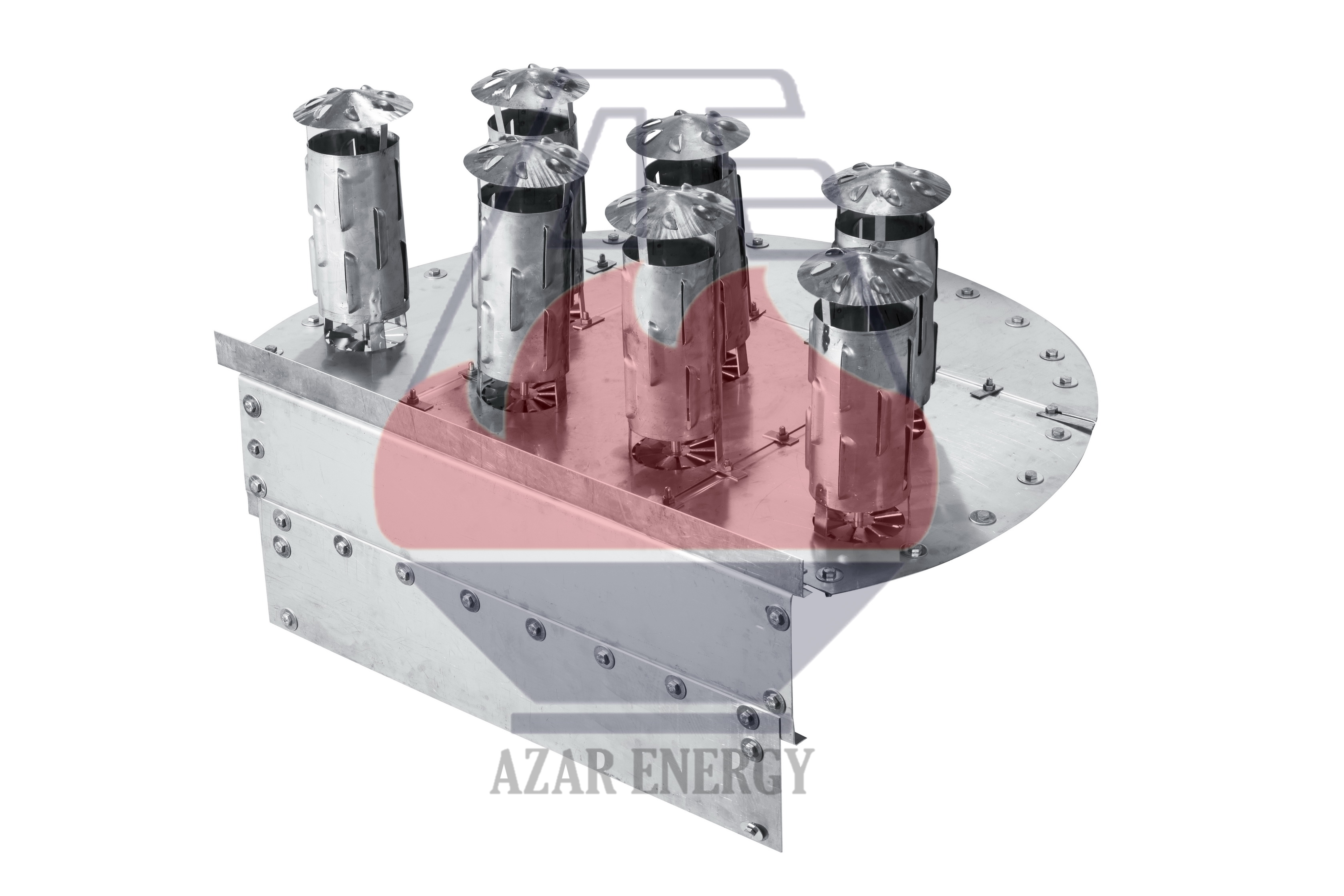

Azar energy high efficiency Tray

One of the most modern trays designed and manufactured using the latest science and modern technologies at Azar energy Tabriz, is the centrifugal trays with mechanism of centrifugal force and special design for phases separation. The features of this type of tray is high capacity, efficiency, mechanical resistance as well as reduced foam and plugging. These trays have remarkable differences with common trays from the viewpoint of geometrical structure, as such this restructuring is very influential on their separation, range and quality of performance. The centrifugal tray belongs to a new generation of mass transfer trays that can increase the capacity and efficiency profile of tray columns significantly. This increase is achieved by a special vapor and liquid distribution and also contact system installed on this tray. In this type of tray, the gas flows from the bottom through angular vanes into the tray in a rotating manner. This type of gas injection causes a pressure difference at the gas inlet section of the tray and the fluid around the gas inlet is sucked into the duct and combined with the gas flow and moving upward with the rotational flow pattern. During this route mass transfer operation take place between phases. In order to separate the phases from each other, slots were prepared on the risers and the caps. Due to the centrifugal force and liquid and gas density difference, the liquid flows out of the slots of riser and flows toward the liquid bulk on tray. This liquid travels all the way to the tray downcomer and mechanism described above is repeated in each gas inlet. The rotational flow created in these trays results in a uniform distribution of the liquid phase on the tray and uniform resistance to gas flow, increasing the effective tray surface area and removing dead surfaces, thereby increasing tray efficiency over conventional trays.